I wanted to know if you can sand foam core board that you can get from a dollar store, but I couldn’t find any definitive answers. So for anyone else wanting to know, yes, it can be sanded. Whether it sands the way you want might depend on what you want it sanded for and what the application is.

I wanted to create a silhouette for a shot of an old gas pump. This depends on having curved edges. It is mostly hidden and other than the top probably underexposed so I am not sure the surface matters too much (I’ll find out!)

But I plan to have the top of it lit so I have to decide whether I will repair the top if it in photoshop or find a way to make the surface more cohesive say by sealing it with something or resurface it.

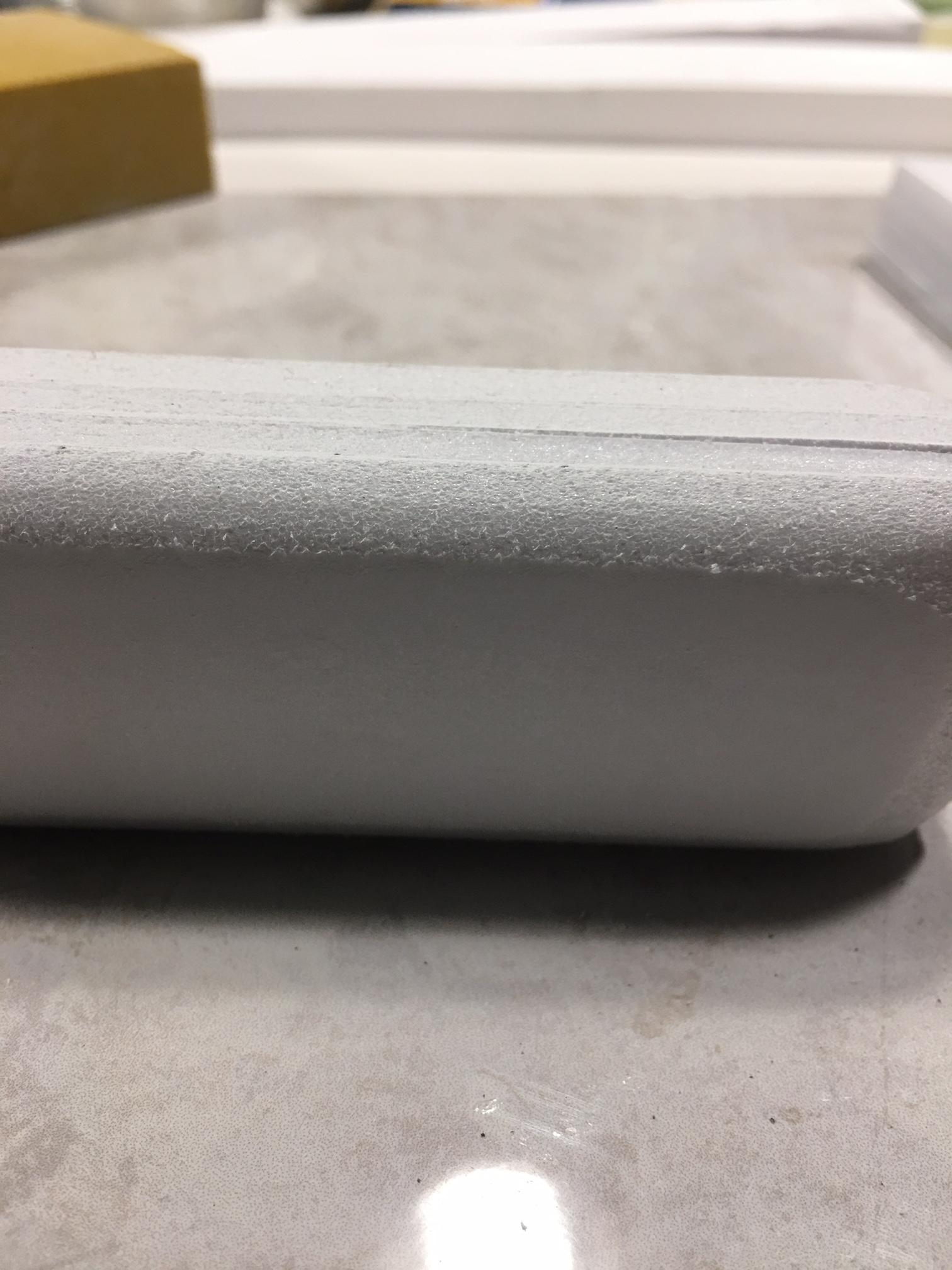

Either way here they are looking like right now. In the first picture you can see the sanded edges version on the left and a version of what I started with on the right.

It doesn’t look like a gas pump, does it?

These are layered and glued pieces of foam core board. You can see those jagged pulls because my blade was not sharp enough. Cutting foam dulls blades fast. You are not going to get that out unless you sand a lot. Better to use a sharp blade and get it right. Since I am no planning on shooting the sides (at least in my first image attempt), I’m good for now. And if not, I’d be looking to cover the surface most likely anyway.

When you get to the paper in between the layers, the paper is more resistant to sanding. It could be related to the glue, but I think the foam is just softer to sand. You can see it with the first edge with how the curve blends into the side. There is a distinct edge, but you have to watch that you don’t take out more of the foam than the paper when you’re sanding. It’s going to give more. Maybe a hard sanding block would be best. I’ve been using flexible ones. But you might want to try thicker foam if it comes to that.

It might also be a good idea to try peeling the paper off. I’ve never done it but I think you can soak it for a bit and remove it that way. I might have to do that if this doesn’t work out. The current lockdown in my area doesn’t make getting materials quickly much of an option.

Again, I think it’s fine for my purposes. I’ll see when it gets to lighting it. Right now it’s not worth the time to get it perfect until I know what I am dealing with.

The other issue is the surface texture. I used a variety of sandpaper grits. 320 was the finest I used. Don’t think I need to try and smoother grit – don’t feel it will make a big enough difference. You are not going to get it super smooth and there is a big difference between that and the paper. I don’t know if you can seal it with something and then sand that or again perhaps think about removing the paper (but I don’t know if that presents new issues such as glue remnants).

That second shot is not sharp, but you can still see the texture and you see how the light falls off on the end side of the curve compared to how the paper looks. If you are building design prototypes, it might not matter to you. But if you are making miniatures, it might. I’m hoping to use photoshop to take care of it.

So in view of being efficient with time, I will try working with this shape first. I learned from making that radiator (that I still had to fix in photoshop) is getting these things perfect in reality can be very time-consuming. It can still take a long time in photoshop and if it doesn’t look real enough what’s the point? So it’s definitely a balancing act. It certainly wouldn’t be the first time I’ve had to rebuild something or reshoot something!

I’d be curious for any of the model builders or miniatures makers out there whether some air dry clay or some other surfacing solution could be a quick fix like glue or mod podge, (some kind of heat shrink plastic that wouldn’t melt foam core – is that a thing – somehow I doubt it). Dippable epoxy? I’ve never used epoxy.

Either way, if you are looking for answers regarding sanding foam core, here is my experience! Hope it helps someone!